FROM DESIGN TO DELIVERY

TOTAL SOLUTIONS FOR

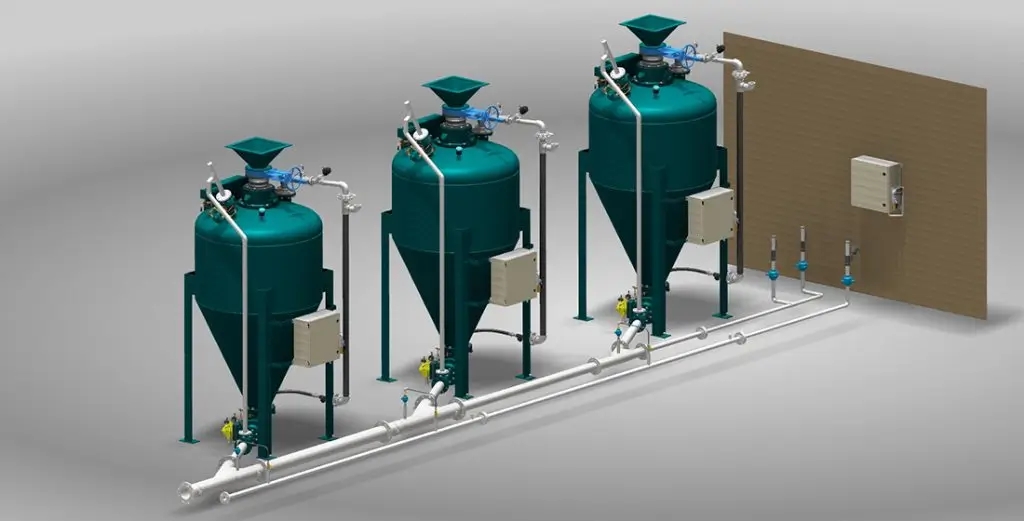

PNEUMATIC CONVEYING SYSTEM

PNEUMATIC CONVEYING

WELCOME TO YIZEBOGE

Powder Material Conveying Since 2010

With over two decades of expertise, we specialize in the design, manufacturing, and servicing of high-quality pneumatic conveying systems and powder transfer equipment. As a trusted leader in the industry, we combine cutting-edge technology with innovative solutions to meet the evolving needs of our clients across the globe.

M² FACILITY SPACE

YEARS EXPERTISE

PATENTS ACHINEVED

SATISFIED CUSTOMERS

Precision Solutions for Every Industry

Generic systems often fail to address the specific needs of high-demand industries, YIZEBOGE delivers industry-specific pneumatic conveying solutions tailored to mission-critical applications across sectors.

HOW OUR PROCESS WORKS

ENGINEER CUSTOMIZED SOLUTIONS

MANUFACTURE TO WORLD-CLASS STANDARDS

DELIVER END-TO-END SUPPORT

Innovative Pneumatic Conveying Solutions for Your Industry

As your trusted partner in pneumatic conveying systems, we collaborate with your team to optimize material handling processes, improve productivity, and ensure the highest standards of precision, efficiency, and reliability.

- OPTIMIZED PNEUMATIC CONVEYING SYSTEMS

- CUTTING-EDGE TECHNOLOGY

- RELIABLE EQUIPMENT PERFORMANCE

- ON-TIME DELIVERY AND INSTALLATION

- SEAMLESS SYSTEM INTEGRATION

- EXPERIENCED ENGINEERS AND AFTER-SALES SUPPORT

Our Cases

News

- August 12, 2021

- Posted by Andre Lindo

As your precision motion partner, we work closely with your team to improve your processes, products and productivity.

- August 12, 2021

- Posted by Andre Lindo

As your precision motion partner, we work closely with your team to improve your processes, products and productivity.

- August 12, 2021

- Posted by Andre Lindo

As your precision motion partner, we work closely with your team to improve your processes, products and productivity.

- March 28, 2025

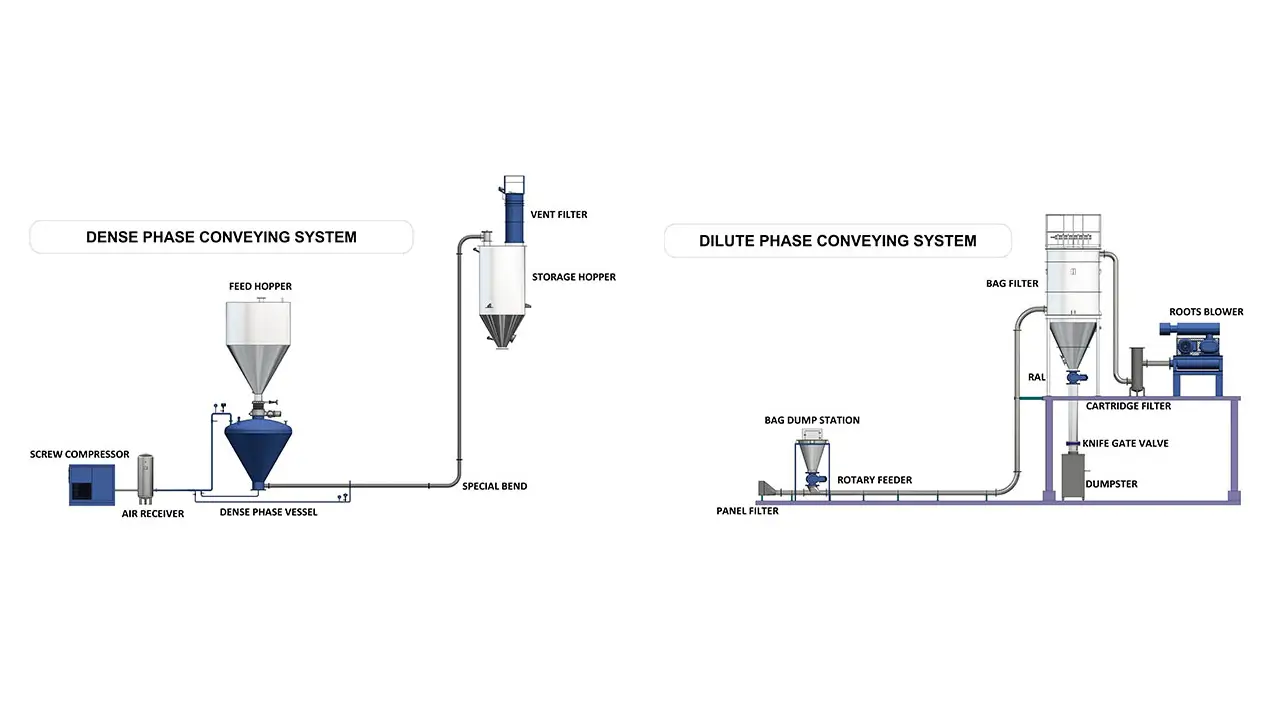

Selecting the optimal pneumatic conveying system—whether dilute phase or dense phase—begins with understanding your material flow characteristics. Once that’s determined, consider these key design aspects: Facility Design Considerations: Process Connection:

- March 28, 2025

Pneumatic conveying systems are highly automated solutions that transport various types of materials through enclosed pipelines. Selecting the right system based on the material’s characteristics is key to achieving optimal

- March 28, 2025

Pneumatic conveying systems are generally divided into two main types: 1. Dilute Phase Conveying Working Principle:Material is suspended and transported within a high-velocity airstream. Key Parameters: Air Velocity: High

Frequently Asked Questions

1. How does YIZEBOGE’s Vibratory Activation Hopper resolve material bridging and arching?

YIZEBOGE’s vibratory activation hopper employs conical/spherical activator units to decompose horizontal vibrations into normal and tangential forces , effectively disrupting internal arch structures within materials. Its centrifugal force vibration technology and hermetic sealing design ensure reliable operation in high-dust environments (e.g., chemicals, building materials), enabling continuous discharge. Typical applications include anti-blockage solutions for lithium battery raw materials and ultrafine powders (e.g., calcium carbonate) .

2. How to select between U-Trough and Tubular Screw Conveyors?

U-Trough Screw Conveyor: Designed for short-distance, high-capacity handling of coarse-grained materials (e.g., cement, coal), offering cost efficiency and simplified maintenance. Tubular Screw Conveyor: Ideal for long-distance, precision conveyance of fine powders (e.g., food-grade additives, lithium cathode materials), featuring enhanced sealing and customizable incline angles (0°–30°). YIZEBOGE provides free material testing and 3D dynamic simulation to optimize equipment selection.

3. How does the Pulse Jet Bag Filter achieve ≥99.9% dust removal efficiency?

YIZEBOGE’s pulse jet filter utilizes multi-chamber pulse jet cleaning technology , paired with high-temperature silicone gaskets and anti-static filter bags , to deliver periodic high-pressure reverse airflow for thorough dust removal. This design minimizes pressure drop, extends filter life, and handles high dust loads in applications like cement kiln exhaust and metal smelting.

4. How does the Feeder Valve ensure ±0.1% flow accuracy in pneumatic systems?

The feeder valve integrates a variable frequency drive (VFD) motor and multi-vane rotor assembly , enabling real-time speed adjustment via closed-loop feedback for ±0.1% dosing precision . Its externally mounted bearings prevent dust ingress, making it suitable for metering ultra-fine powders (e.g., chemical catalysts) .

5. How is material homogenization achieved in YIZEBOGE silos?

YIZEBOGE silos incorporate helical baffles or vibration de-arching mechanisms , leveraging gravitational stratification to blend materials of varying particle sizes/densities during storage. Case studies include coal powder homogenization and plastic pellet batch consistency control.

6. Does YIZEBOGE support equipment customization?

Yes. Our modular engineering services cover: Dimensional customization: Tailored inlet/outlet configurations (round/square) and materials (stainless/carbon steel). Functional upgrades: Integration of temperature sensors , load cells , or IoT-enabled remote monitoring . Notable projects include corrosion-resistant systems for chemical plants and sterile conveying lines for food processing.

7. How is wear resistance ensured in screw conveyors?

YIZEBOGE utilizes dual-layer wear-resistant liners with tungsten carbide coatings or ceramic inserts , tripling lifespan in abrasive applications (e.g., sand, crushed glass). All units undergo 72-hour endurance testing and come with a 1-year warranty + lifetime technical support.

8. How are cross-equipment synergies managed in integrated systems?

YIZEBOGE delivers turnkey solutions with PLC-based central control systems for seamless coordination: Automated process logic: Synchronizes feeders, conveyors, and dust collectors via preset workflows. Real-time dashboards: Monitor pressure, flow, and temperature, with remote diagnostics and energy optimization. Example: Closed-loop material handling for battery production lines, boosting efficiency by ≥20%.

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.