MAGNETIC MATERIALS

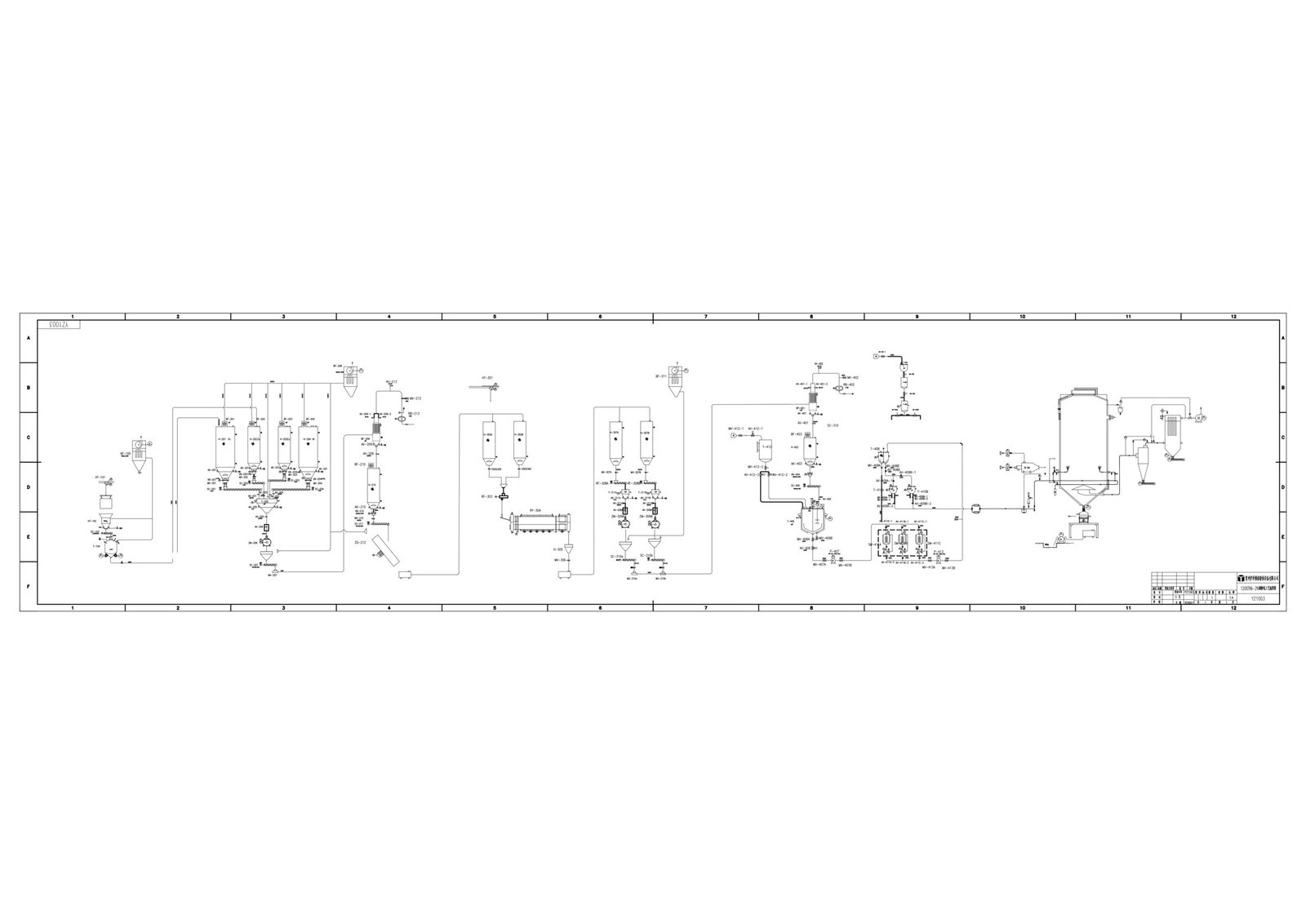

Magnetic Material Production Line

Three Key Values

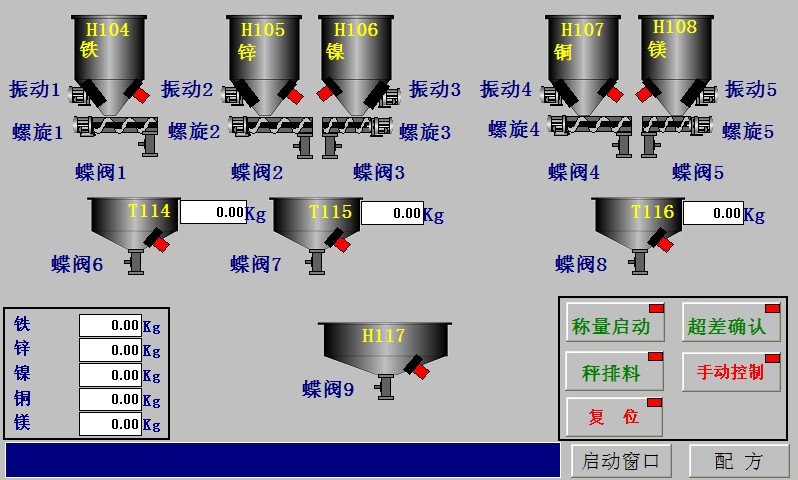

- Material Integrity & Purity Preservation

- Closed-Loop Design:Prevents oxidation, contamination, and moisture absorption of magnetic powders (e.g., ferrite, rare-earth alloys), ensuring consistent quality and performance.

- No Direct Contact:Eliminates physical interaction with operators or equipment, significantly reducing cross-contamination risks.

- Efficient & Precise Material Handling

- Automated Bulk Transfer:Provides high-accuracy dosing for blending and mixing processes, which is critical for maintaining optimal magnetic properties.

- Optimized Production Flow:Minimizes downtime by preventing manual feeding errors and pipeline blockages, enhancing overall throughput.

- Occupational Safety & Environmental Compliance

- Dust Control:Integrated filtration systems reduce dust emissions, ensuring compliance with air quality standards and improving worker safety.

- Energy Efficiency:Consumes less energy compared to mechanical conveying methods, supporting sustainable manufacturing practices.

These advantages make pneumatic conveying an essential solution for achieving high-purity, scalable, and eco-friendly magnetic material production.

Our Solutions

Contact us

- 11 Qingyang Rd, 213125, Changzhou, China

- +86-519-86661007

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.