BUILDING MATERIALS

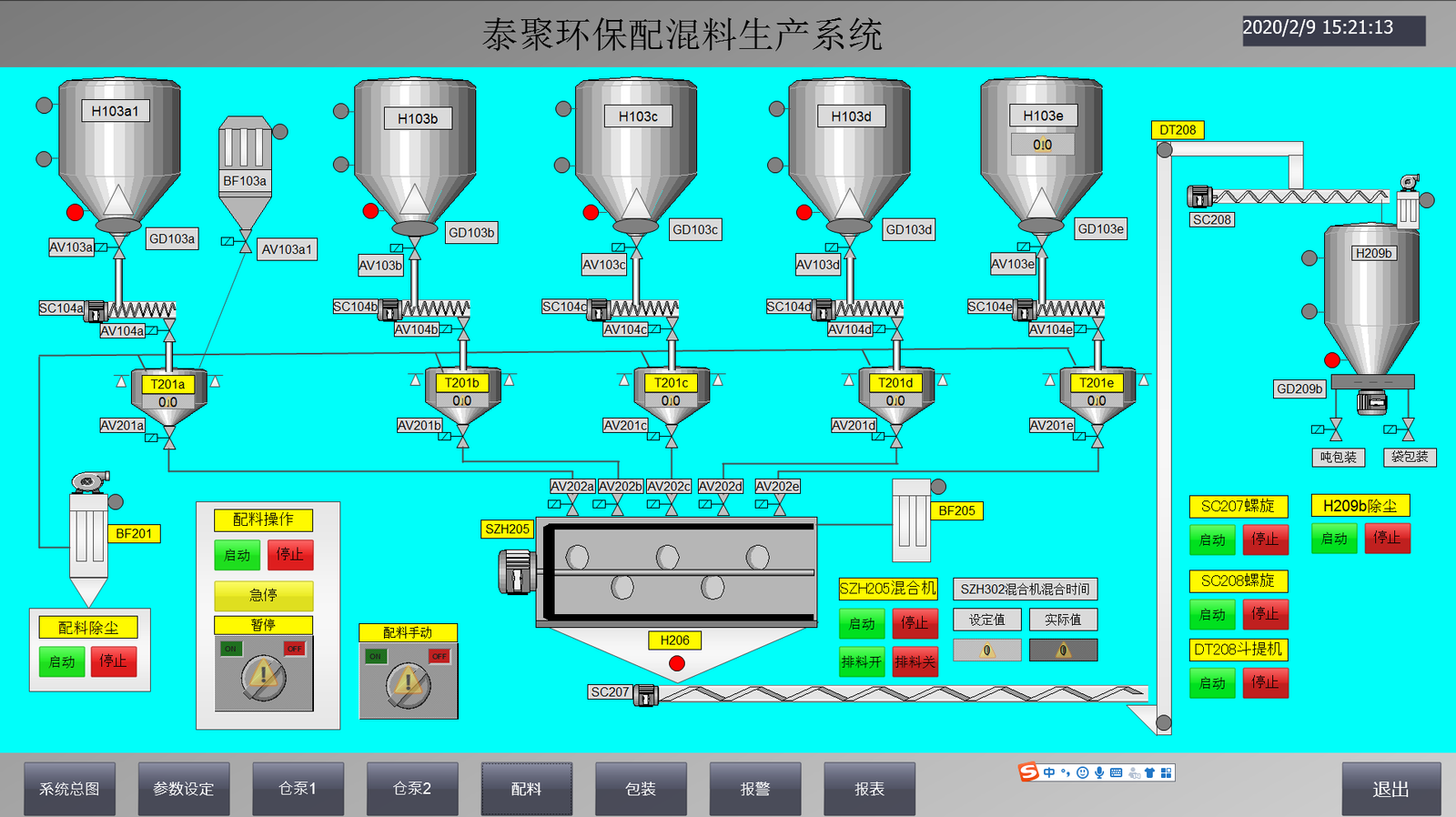

Powder Conveying and Batching System

Our Powder Conveying and Batching System is a cutting-edge industrial automation solution designed to precisely blend various bulk materials—both powders and liquids. By integrating high-accuracy weighing systems, control instruments, PLCs, and supervisory computers, the system guarantees efficient and consistent batching processes.

Key Functions

- Automated Data Processing

Seamlessly processes collected signals to control equipment operations, ensuring smooth and efficient batching. - Two-Way Communication

Enables real-time data exchange between the industrial computer, PLC, and instruments for synchronized operation. - Comprehensive Monitoring

Continuously tracks key parameters—including instantaneous flow rate, and daily, monthly, and annual cumulative data—to maintain process integrity. - Real-Time Display

Provides immediate visual feedback on control parameters and operational status via computer monitors or weighing instruments. - On-Demand Reporting

Generates and prints detailed batching reports for record-keeping and analysis, with user-selectable options. - Alarm and Fault Detection

Instantly alerts operators to parameter deviations or equipment abnormalities using screen notifications and audio-visual signals, while the PLC manages real-time control and fault detection.

Main Applications

- Magnetic Material Batching System

- PVC Powder Batching System

- Calcium Carbonate Filler Batching System

- Flour Batching and Mixing System

- Film Production Line Powder Batching System

Our Solutions

Contact us

- 11 Qingyang Rd, 213125, Changzhou, China

- +86-519-86661007

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.