PLASTICS INDUSTRY

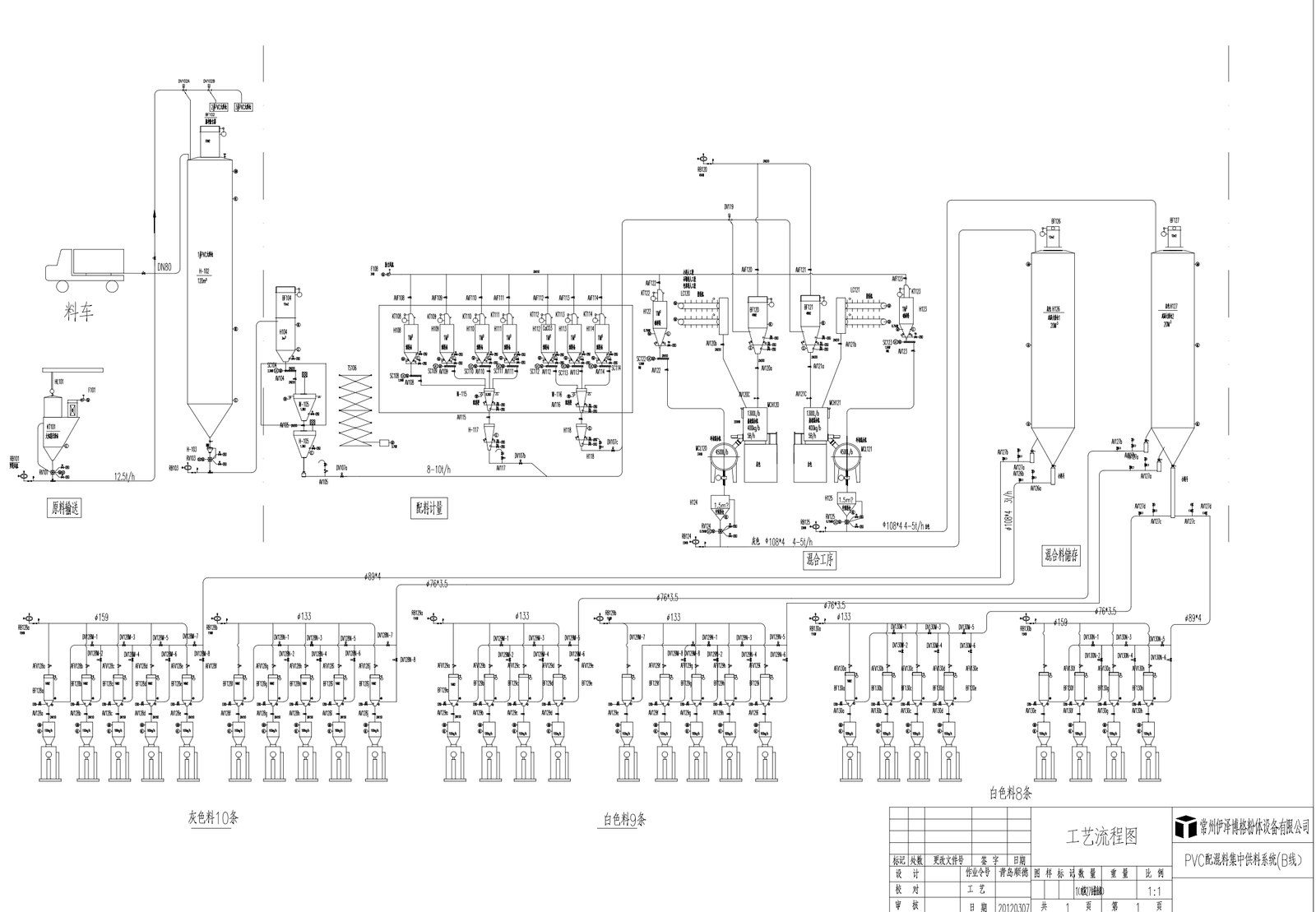

Centralized Feeding System for the Plastics Industry

Key Features:

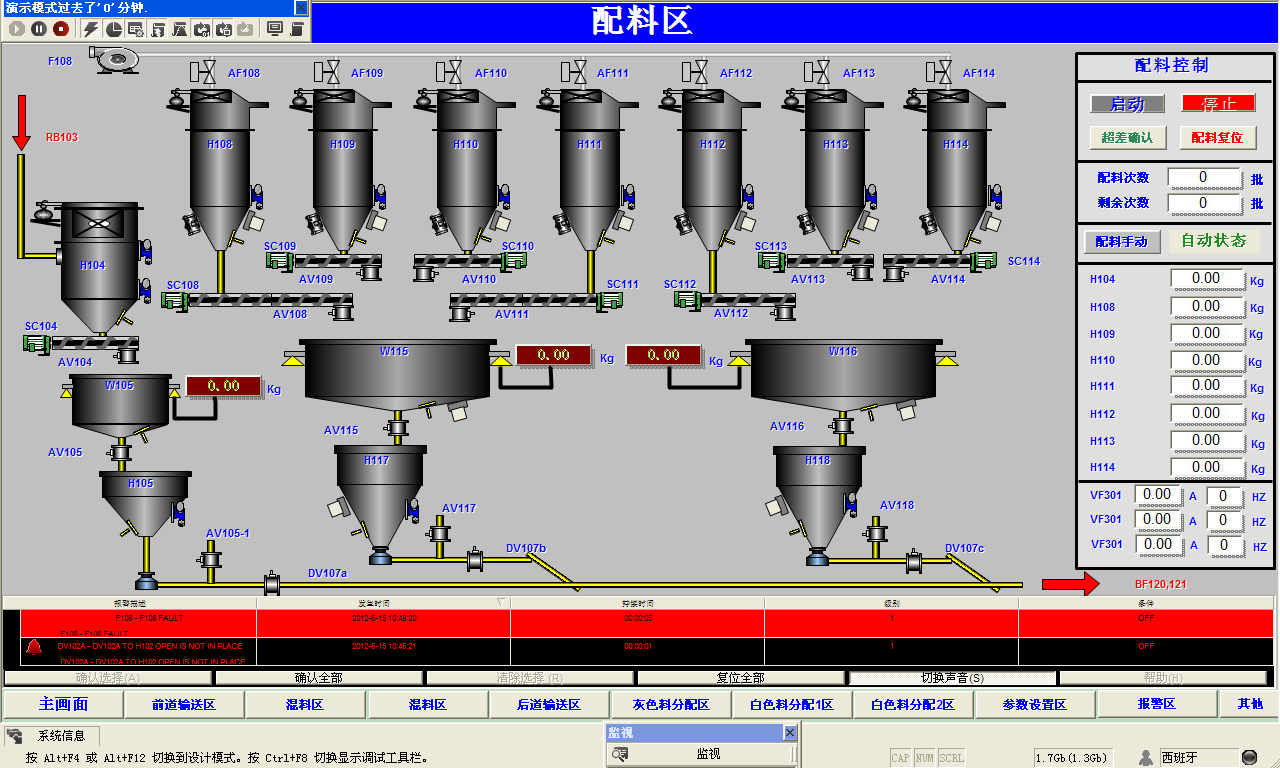

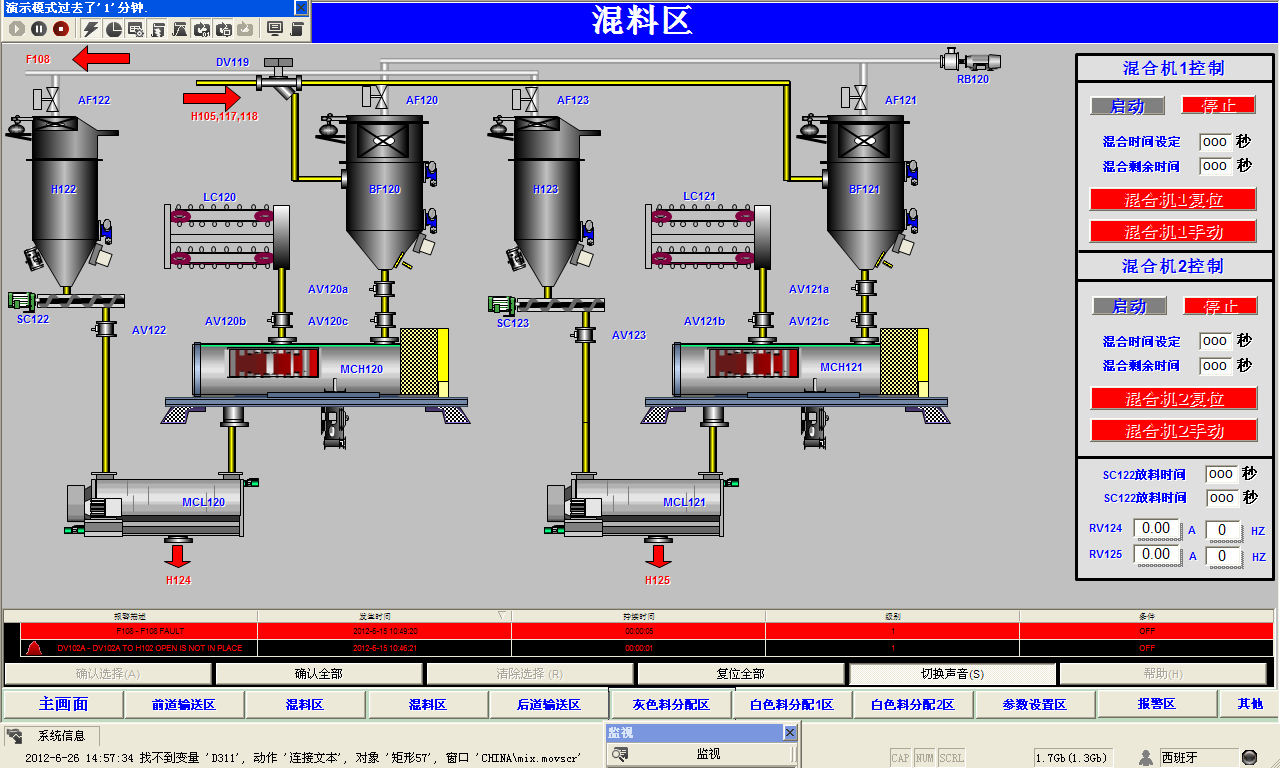

• Computer‑Controlled Automatic Blending

Utilizing state‑of‑the‑art pneumatic conveying technology, the system ensures precise metering and rapid blending of raw materials. It minimizes human error and chemical exposure while enhancing batching accuracy and throughput—specifically engineered for large‑scale plastics suppliers.

• Automated Pneumatic Transport

A vacuum or pressure‑driven network automates material transfer between process stages. By reducing manual intervention, it lowers labor costs and accelerates production cycles, thereby boosting overall plant productivity.

• Closed‑Loop, Dust‑Free Conveying

Materials are conveyed through fully sealed pipelines to prevent dust emissions and maintain a clean production environment. Integrated pulse filters and dust collectors further mitigate contamination risks, ensuring compliance with stringent industry hygiene standards.

Our Solutions

Contact us

- 11 Qingyang Rd, 213125, Changzhou, China

- +86-519-86661007

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.