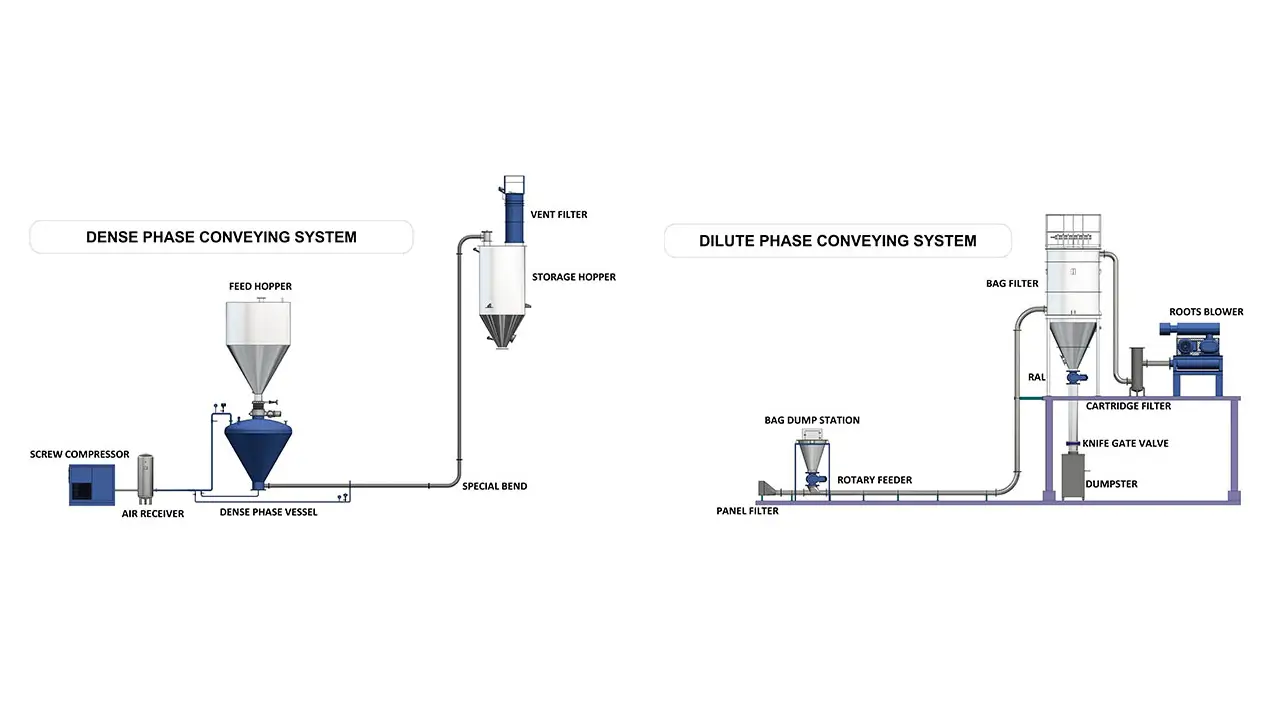

Selecting the optimal pneumatic conveying system—whether dilute phase or dense phase—begins with understanding your material flow characteristics. Once that’s determined, consider these key design aspects:

- Facility Design Considerations:

- Process Connection:

Ensure proper interfacing between production processes by selecting the appropriate inlet and outlet configurations. - Material Characteristics & Process Standards:

Evaluate the properties of the materials and the relevant process standards, as these greatly influence the conveying design. - Environmental Protection:

Address exhaust gas treatment and noise control to meet environmental regulations and create a safe working environment.

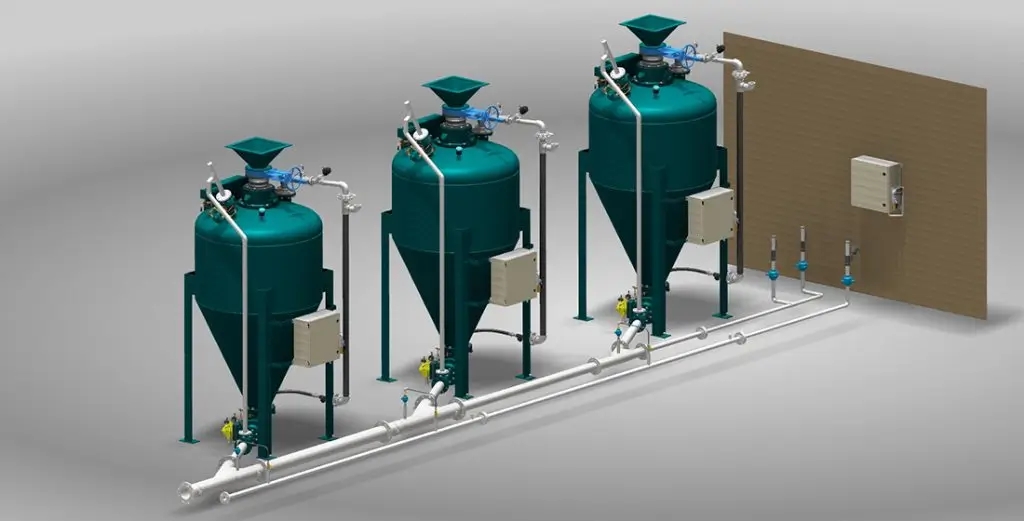

- System Layout:

- Component Placement:

- Position the feeder or suction nozzle at the starting point.

- Locate the separator at the endpoint.

- Arrange the air compressor and ancillary facilities logically within the plant.

- Pipe Configuration:

- Minimize the number of elbows and avoid excessively long horizontal runs to reduce pressure loss.

- Insulate pipes that span indoor and outdoor environments to prevent condensation from temperature differences.

- Fittings:

Avoid placing fittings on material conveying pipes if they could impede smooth flow.

- Determination of Core Components and Structures:

- System Types:

- Suction-Type Systems:Utilize nozzles and separators.

- Pressure-Type Systems:Use feeders and separators.

- Cylinder Conveying:Typically incorporates transmitters.

- Reciprocating Conveying:May include exchange stations.

- Automation:

Integrate automatic control systems (program-based and route management) to enhance reliability and efficiency.

- Rough Estimation of System Energy Requirements:

- Energy Calculation:

Estimate energy needs as the product of required air volume and pressure. - Pressure Loss Estimation:

Perform rough calculations of system pressure loss to help size the compressor appropriately.

- Accurate Measurement of System Data:

- Detailed Analysis:

After establishing the initial system scheme, conduct precise, component-by-component calculations to finalize dimensions and ensure optimal performance.