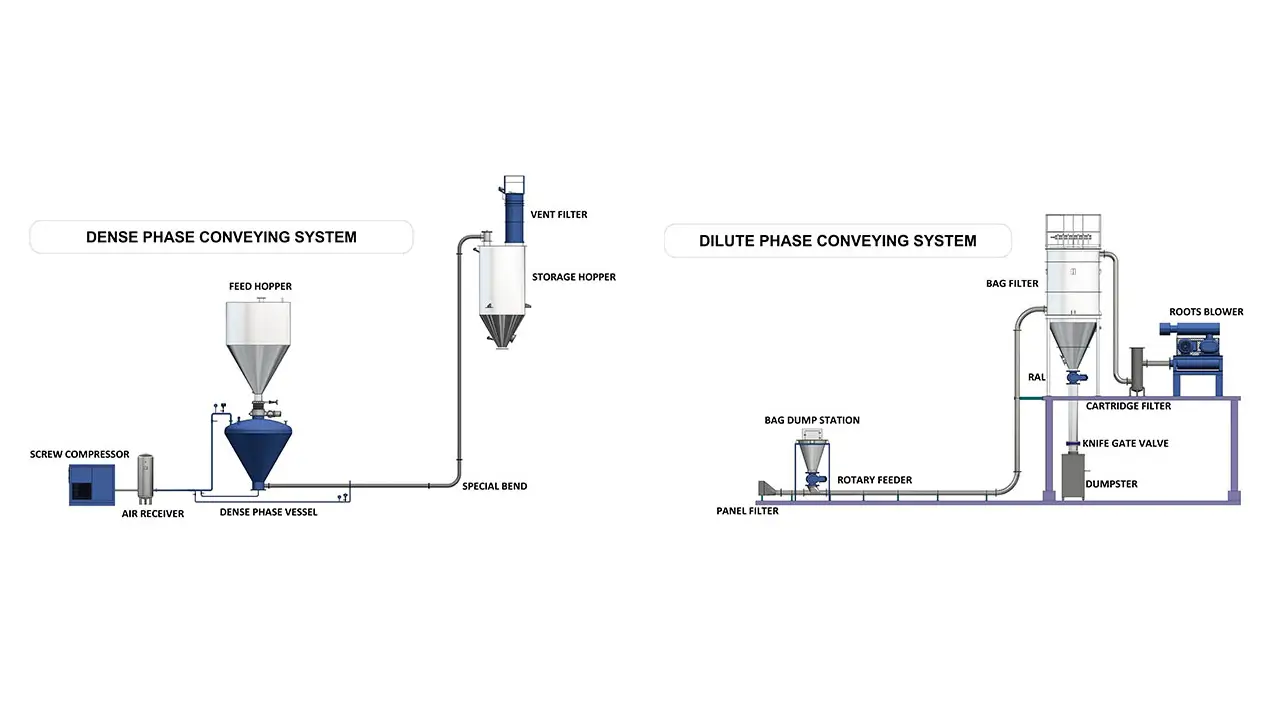

Pneumatic conveying systems are generally divided into two main types:

1. Dilute Phase Conveying

-

Working Principle:

Material is suspended and transported within a high-velocity airstream. -

Key Parameters:

-

Air Velocity: High (18–30 m/s)

-

Pressure: Low (0.02–0.09 MPa)

-

Distance: Best suited for short distances (≤300 meters)

-

Dust Concentration: Suitable for low to medium concentrations (1–10 kg/m³)

-

-

Advantages:

-

Lower initial investment

-

Simpler maintenance

-

Broad material compatibility (suitable for nearly all bulk solids)

-

-

Disadvantages:

-

High velocity may lead to material degradation, excessive dust generation, and increased pipe wear

-

Higher energy consumption, especially in short-distance or small-batch applications

-

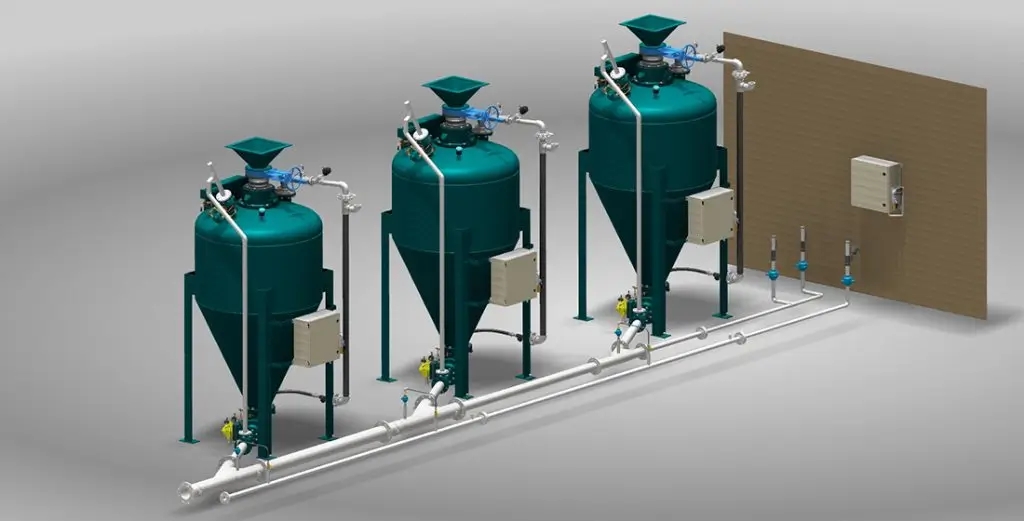

2. Dense Phase Conveying

-

Working Principle:

Material is conveyed in a plug flow or slug form, not suspended in the air stream. -

Key Parameters:

-

Air Velocity: Low (2–10 m/s)

-

Pressure: High (0.3–0.7 MPa)

-

Solid-to-Gas Ratio: High (≥25)

-

-

Advantages:

-

Reduced pipeline wear and minimal material degradation—ideal for fragile materials (e.g., lithium battery powders)

-

More energy-efficient for long-distance conveying

-

-

Disadvantages:

-

Requires systems capable of delivering high pressure

-

Higher installation cost due to larger pipe diameters

-

How to Choose Between Dilute and Dense Phase Conveying?

-

Material Characteristics:

-

Use dilute phase for non-abrasive, fine particles (e.g., plastics, food ingredients).

-

Use dense phase for abrasive, fragile, or sticky materials (e.g., cement, fly ash).

-

-

Distance and Pressure Requirements:

-

Dilute phase is preferred for conveying distances under 300 meters.

-

Dense phase is ideal for distances beyond 300 meters, provided adequate pressure is available.

-

-

Economic Considerations:

-

Balance the lower initial cost and simpler maintenance of dilute phase systems against the long-term energy savings and reduced material damage offered by dense phase systems.

-