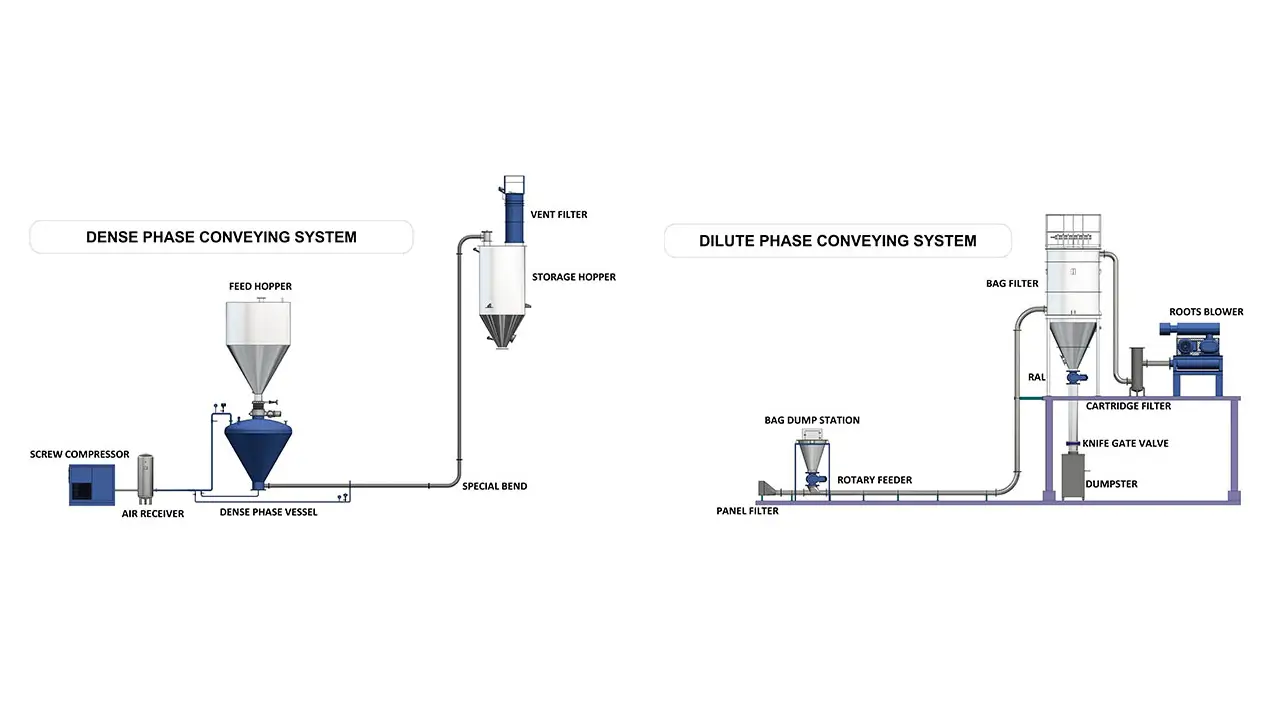

Pneumatic conveying systems are highly automated solutions that transport various types of materials through enclosed pipelines. Selecting the right system based on the material’s characteristics is key to achieving optimal efficiency and reliable performance.

Follow these best-practice guidelines to choose the optimal solution for your process:

1. Select the Right Feeder Based on Material Viscosity

- For sticky or cohesive materials prone to clinging and clogging hoppers or pipelines, use rotary feeders with rotating blades to ensure consistent flow.

2. Implement Safety Measures for Flammable and Explosive Materials

- When conveying hazardous materials like plastics, chemicals, metal powders, or coal dust, install explosion-proof valves and rupture discs to ensure operational safety.

3. Optimize for Moisture-Containing Materials

- Dry and fine powders (particle size < 50 µm, moisture content < 10%) can usually be conveyed effectively using standard pneumatic systems.

- For moist materials prone to buildup and clogging, consider:

- Rotary blow-through feeders for improved material flow

- Pre-heated or dried conveying air to reduce adhesion if the material is not excessively wet

4. Manage Static Electricity

- Use antistatic grounding and bonding to prevent electrostatic charge accumulation and discharge hazards.

5. Minimize Material Degradation

- Design the layout to reduce sharp bends and sudden direction changes, keeping conveying velocity low to prevent material breakage.

6. Prevent Hygroscopic Absorption

- Use dry conveying air to prevent moisture absorption. For sensitive materials:

- Employ desiccant dryers or refrigerated air treatment

- Consider dense phase conveying with dried air

7. Handle Fine Powders Effectively

- Micron and submicron powders tend to adhere to pipe walls, reducing conveying capacity. Solutions include:

- Flexible hoses

- Periodic vibration or pulsation to prevent buildup and blockages

This structured approach ensures the conveying system is tailored to material-specific challenges, enhancing throughput, reducing downtime, and increasing overall system reliability.