NEW ENERGY MATERIALS

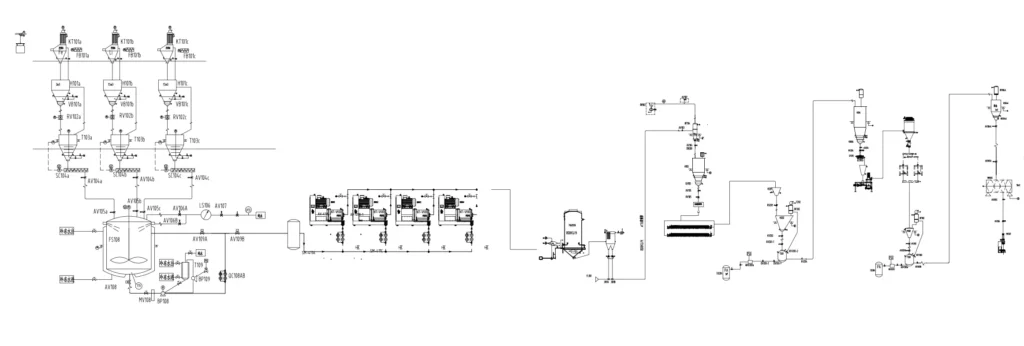

Lithium Battery Powder Pneumatic Conveying System

Enhance your lithium battery production with our advanced pneumatic conveying solutions, engineered for precision, hygiene, and energy efficiency. These systems address the stringent requirements of modern battery manufacturing by delivering unparalleled performance and reliability.

Three Core Advantages

1. Ultra High Precision & Dust Free Handling

– High‑accuracy metering modules

– Advanced filtration system

– Automatic purge (blow‑through) functionality

2. Wear Resistance & Safety Compliance

– Wear‑resistant coatings on all contact surfaces

– Metal‑isolated, abrasion proof ceramic tubing

3. Energy Efficiency & Scalable Design

◦ Low Energy Consumption: High‑pressure exhaust reduces power draw, and modular piping allows rapid reconfiguration for different powder formulations.

◦ Flexible Expansion: Scalable, modular architecture that integrates seamlessly with existing lines and supports future capacity increases.

By preserving material purity, enforcing rigorous hygiene standards, and optimizing energy use, this solution tackles the key challenges of lithium‑battery manufacturing. The result: enhanced cell performance, improved production reliability, and a solid foundation for superior product quality and operational excellence.

Our Solutions

Contact us

- 11 Qingyang Rd, 213125, Changzhou, China

- +86-519-86661007

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.